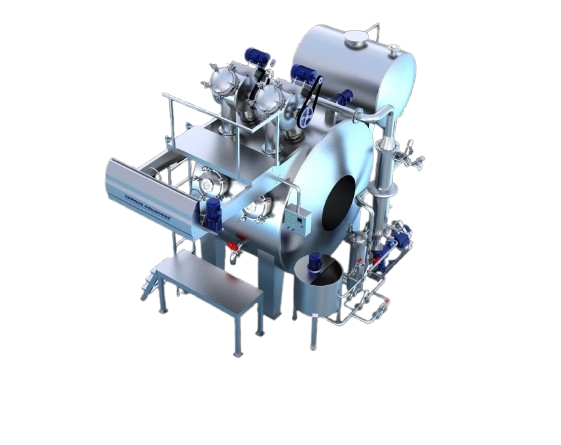

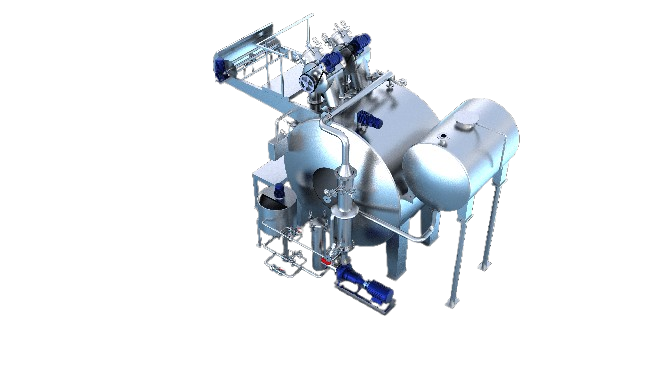

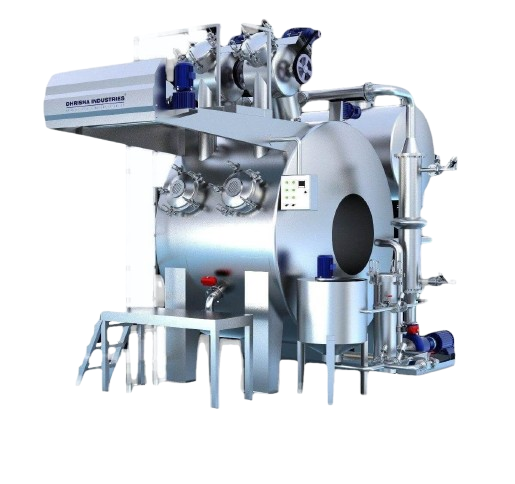

Low Liquor Ratio Color Charge HT Sample Dyeing Machine

Standard Feature :

- The machine body and major parts in contact with the dye liquid are made of Stainless Steel 316L, ensuring high corrosion and acid resistance.

- Highly efficient vertical heat exchanger for fast heating and cooling, preventing scale formation.

- Highly efficient, heavy-duty stainless steel centrifugal pump with frequency control and a mechanical seal to prevent leakage.

- The machines are controlled via an industrial PLC with an air-conditioned stainless steel control panel to prevent moisture formation inside the panel.

- Automatic adjustable nozzle based on fabric nature.

- Mechanical lock operates with vessel internal pressure impact.

- Smart dosing and salt dosing function.

- Observing window with a stainless steel grid.

- Internal main body washing system.

- LED lighting system inside the main body.

- Seam detection and cycle control system.

- Additional tank for reserve tank transfer.

Technical Data:

- Stainless Steel 316L body with high corrosion and acid resistance.

- Maximum working temperature: 140°C.

- Inner rotating fabric chamber for smooth and secure fabric transport.

- Heating Rate:

25°C – 100°C: Average 4°C/min.

100°C – 130°C: Average 2°C/min. - Cooling Rate:

130°C – 100°C: Average 3°C/min.

100°C – 85°C: Average 2°C/min.

500 KG. SOFT FLOW MACHINE

- Adjustable Nozzle System

Each nozzle is equipped with an adjustment system controlled by an individual actuator. The nozzle position can be adjusted steplessly by this actuator. A wide variety of fabrics can be dyed in tubular and open-width forms without any penetration problems, thanks to the adjustable nozzle system. - Lid System

The loading/unloading lids are equipped with an automatic safety locking system.

- Automatic Process Control System

Automatic control of all dyeing processes. All machine parameters, dosing functions, pump speed, inner reel speed, heating/cooling system, nozzle position, fabric cycle time, etc., can be easily controlled via the operator control panel. - Side Tanks

Two side tanks for dyestuff and chemical materials. Both tanks are equipped with a heating system, stirrer, and level measuring system. The dosing function (linear, progressive) is performed automatically by means of a dosing pump and related valve. - Inner Reel

Each inner reel is driven by an individual frequency-controlled motor. Reel speed up to 450 m/min. Excellent mechanical durability of the inner reel mechanism is ensured by the reel shaft and bearing housing design. The mechanical seals are problem-free for a very long time due to this mechanism. - Stock Tank (Optional)

1:4 liquor volume capacity stock tank located in a horizontal position. Equipped with a circulation pump, heating system, and level measuring system. The hot water required for the next step of the process is prepared in this tank at the desired temperature.

- Stock Tank (Optional)

1:4 liquor volume capacity stock tank located in a horizontal position. Equipped with a circulation pump, heating system, and level measuring system. The hot water required for the next step of the process is prepared in this tank at the desired temperature. - Plaiter System

The frequency-controlled plaiter system is synchronized with the inner reel speed. It ensures the even stacking of fabric in the J-fabric basket. It is available for 200 kg and 250 kg J-fabric baskets. - Main Circulation Pump

High-efficiency circulation pump made of stainless steel with frequency-controlled pump speed. - Proportional Heating and Cooling System

The heating and cooling gradients are adjusted to the desired values by means of a proportional valve, and the valve position is controlled by an IP converter.